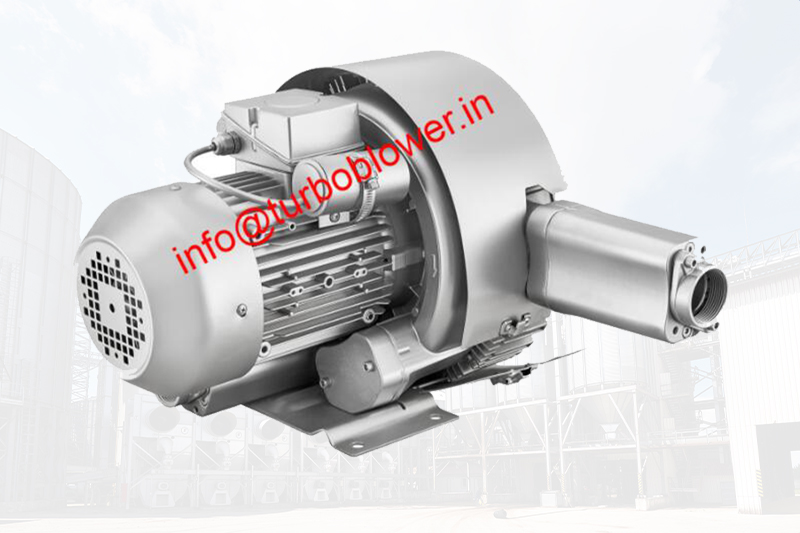

Side Channel Blower

Side Channel Blowers are suitable for all those applications requiring considerably higher pressures than that which can be achieved using centrifugal fans. Side channel blowers are used in all those applications requiring an operating vacuum higher than the one achievable by a fan, but not as high as to require the use of a vacuum pump. The rotating parts of the blower are not in contact with the casing, there is therefore no friction during operation and thus no internal lubrication is necessary. The gas moving through the machine therefore remains uncontaminated and completely oil-free.

The use of Turbo side channel blowers is common in machine-building as high pressure ventilator, vacuum pump, air pump, booster, low pressure compressor and oil-free compressor. The applications are unlimited like aireting, dust cleaning, vacuum lifting, vacuum tables, blowing off, pneumatic transport, cooling and vacuum molding.

Turbo Die cast aluminium side channel blowers are robust units used for versatile applications. These blowers stand out for their durability, due to the robust aluminium design, which makes them highly resistant against corrosion.

Other advantages ofTurbo side channel ventilators include :

- Almost completely maintenance free Have a wide range of performance Robust yet light weight

- Reliability - Built to last

- 50/60 Hz Voltage range motors Low level of noise

- Easy installation

- No vibration, complete dynamic stability Pulsation free discharge

- Simple and minimal maintenance Higher Pressure Ratios

- Cooler Running Bearings

- Longer Grease Life

- 100% Oil Free Air

- Suitable to environment protection Small dimensions

Side Channel Blower Applications :

- Drying out buildings - Ventilating/drying out buildings after flood

- Dental vacuum

- Filling Bags and bottles

- Filling Silos

- Fishpond/breeding pond ventilation - Enriching water with oxygen

- Food processing - Degasification

- Gas analysis

- Industrial vacuum cleaners, central extraction systems

- Lifting and holding parts using vacuum suction

- Laser printers - Powder dusting and extraction

- Letter sorting, enveloping

- Packaging Machines

- Paper Industry - Sheet separation, turning, transport, fixation and drying

- Pneumatic Conveying

- Soil Treatment - Extracting ground level air

- Swimming pool technology/spas - Blowing air into water tanks

- Textile machines - Extracting waste thread and fluff

- Thermoforming

- Ventilation of sewage treatment plants - Enriching water with oxygen

For the three phase machines the tolerance is +/- 10% for fixed voltage range and +/- 5% for regular voltage range.The single phase machines are designed with a +/- 5% tolerance. If only 90% of the maximum allowed pressure will be used for continuous operation then the allowed voltage range adds up to +/- 10%. The frequency tolerance is maximum +/- 2%.

| Item | Model | Kw/Hp | Capacity | Pressure | Vacuum | In-Outlet | Weight | |

|---|---|---|---|---|---|---|---|---|

| E-13 | TBM-229 | 0.4kw / 0.5hp | 90 m3/hr | 120 mbar | 100 mbar | 1.1/4" | 12 kg | View |

| E-15 | TBM-329 | 0.75kw / 1hp | 150 m3/hr | 160 mbar | 150 mbar | 1.5" | 15 kg | View |

| E-21 | TBM-429-2 | 1.1kw/ 1.5hp | 200 m3/hr | 180 mbar | 180 mbar | 2" | 18.5 kg | View |

| E-22 | TBM-429 | 1.5kw / 2hp | 220 m3/hr | 220 mbar | 200 mbar | 2" | 22 kg | View |

| E-25 | TBM-439 | 2.2kw / 3hp | 255 m3/hr | 270 mbar | 240 mbar | 2" | 32 kg | View |

| E-26 | TBM-529 | 2.2kw / 3hp | 340 m3hr | 220 mbar | 230 mbar | 2" | 35 kg | View |

| E-29 | TBM-629 | 3.4kw / 5hp | 355 m3/hr | 300 mbar | 270 mbar | 2" | 40kg | View |

| E-31 | TBM-639 | 4kw / 5.3hp | 330 m3/hr | 325 mbar | 300 mbar | 2" | 47 kg | View |

| E-32 | TBM-729 | 5.5kw / 7.5hp | 555 m3/hr | 345 mbar | 320 mbar | 2.5" | 68 kg | View |

| E-33 | TBM-829 | 7.5kw / 10hp | 620 m3/hr | 400 mbar | 350 mbar | 2.5" | 76 kg | View |

| E-34 | TBM-919 | 9kw / 12.5hp | 1150 m3/hr | 300 mbar | 250 mbar | 4" | 118 kg | View |

| E-35 | TBM-929 | 11.5kw / 15hp | 1250 m3/hr | 360 mbar | 300 mbar | 4" | 130 kg | View |

| E-36 | TBM-939 | 18kw / 25hp | 1300 m3/hr | 380 mbar | 330 mbar | 5.5" | 145 kg | View |

| E-37 | TBM-2308 | 0.75kw / 1hp | 90 m3/hr | 250 mbar | 215 mbar | 1.1/4" | 18.5 kg | View |

| E-38 | TBM-3319 | 1.5kw / 2hp | 156 m3/hr | 320 mbar | 290 mbar | 1.5" | 26 kg | View |

| E-39 | TBM-3326 | 2.2kw / 3hp | 160 m3/hr | 400 mbar | 340 mbar | 2" | 35 kg | View |

| E-40 | TBM-4337 | 3.4kw / 5hp | 240 m3/hr | 425 mbar | 360 mbar | 2" | 47.5 kg | View |

| E-42 | TBM-6346 | 4kw / 5.3hp | 320 m3hr | 490 mbar | 390 mbar | 2" | 55 kg | View |

| E-43 | TBM-6355 | 5.5kw / 7.5hp | 335 m3hr | 510 mbar | 450 mbar | 2" | 88 kg | View |

| E-44 | TBM-6375 | 7.5kw / 10hp | 340 m3/hr | 580 mbar | 470 mbar | 2" | 88 kg | View |

| E-48 | TBM-8315 | 11.2kw / 15hp | 535 m3/hr | 670 mbar | 480 mbar | 2.5" | 128 kg | View |

| E-52 | TBM-9320 | 20kw / 27hp | 1150 m3/hr | 510 mbar | 430 mbar | 4" | 205 kg | View |

| E-53 | TBM-9325 | 26kw / 35hp | 1250 m3/hr | 600 mbar | 450 mbar | 4" | 225 kg | View |

| E-54 | TBM-9420 | 20kw / 27hp | 2200 m3/hr | 240 mbar | 250 mbar | 4" | 240 kg | View |

| E-55 | TBM-9425 | 26kw / 35hp | 2300 m3/hr | 290 mbar | 310 mbar | 4" | 265 kg | View |